ZM Milling

Dedicated stone modelling software for advanced and artistic processing

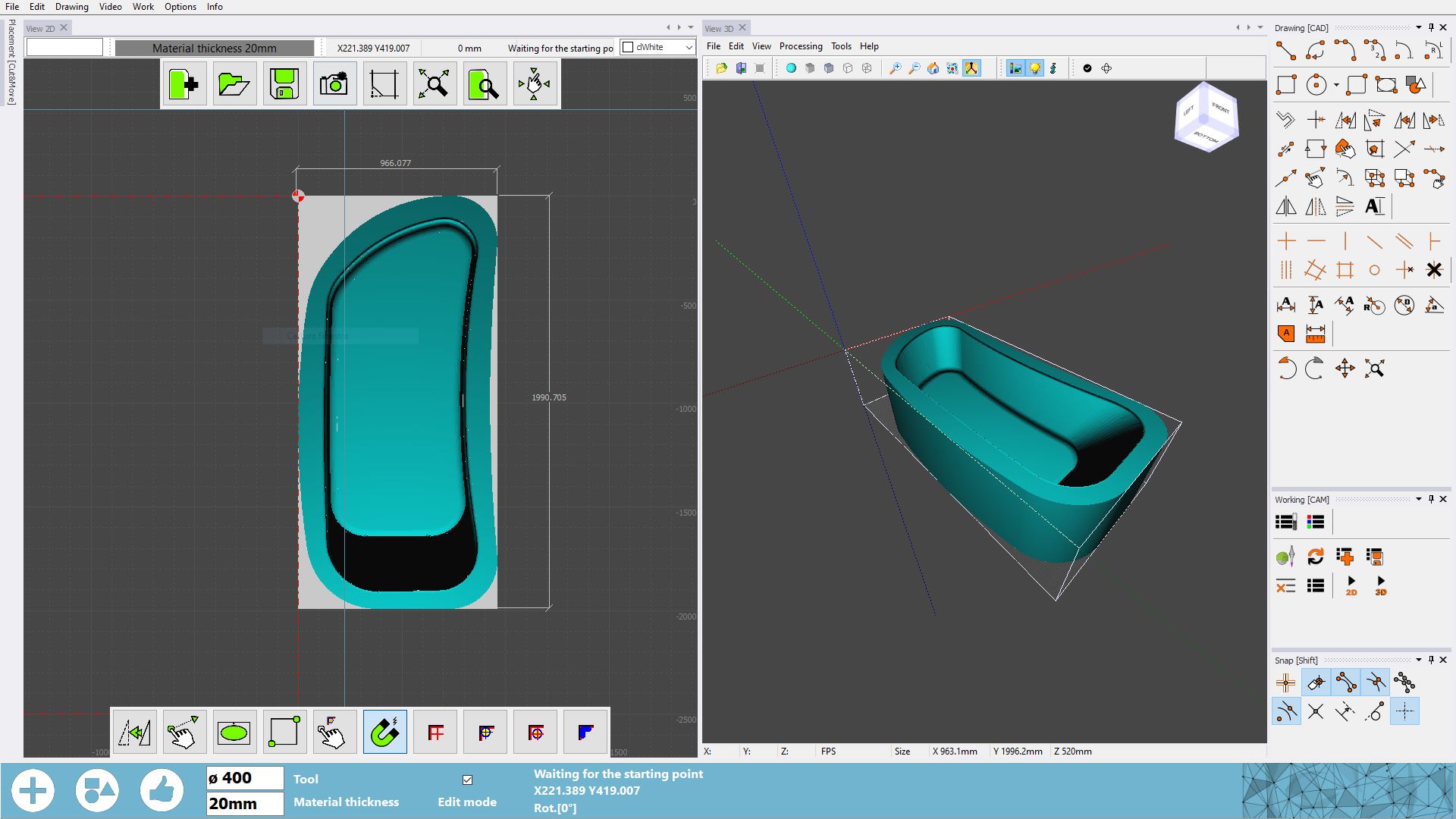

Software for the operation of numerically controlled milling machines for the cutting of stone materials and the realisation of more complex workings such as blocks, shower trays, arches, bath tubs, capitals, columns, bas-reliefs and 3D realisations. ZM MILLING has 2D CAD and 3D CAD modules with functions for creating, modifying and transforming 2D and 3D geometric entities.

Specific module for drawing and editing 2D geometries for the simplified construction of kitchen tops, bathroom tops and sinks. This module also allows the generation of engravings such as lettering along straight or curved lines, on mapping of Windows TrueType fonts, management of construction mode and dimensioning. It also includes automatic or manual nesting and vector printing.

Module for creating and editing primitive 3D geometric figures, solid and surface models, based on NURBS (Non-Uniform Rational B-Splines) mathematical representations and mesh grids. The 3D CAD system allows projection and wrap of geometric figures on surfaces, the creation of 3D macro geometries for the simplified construction of cornices, washbasins, 3D pockets, shower trays, ribbed surfaces and torciglioni. The module has dedicated CAD commands for sculpted surfaces.

2.5D machining

The 2.5D CAD modules for milling, allow machining in three dimensions (x, y and z) but interpolation is limited to the x and y axes. Among the machining operations provided by these modules are:

3D 3+2 AND 4 / 5-axis machining

The 3+2 3D CAD modules on positioned planes and 4 / 5 continuous and interpolated axes are functional for the machining of three-dimensional surfaces through different strategies and functionalities. Here is the complete list:

2D and 3D machining with disc tool

Modules for complete disc tool management for 2D and 3D machining such as:

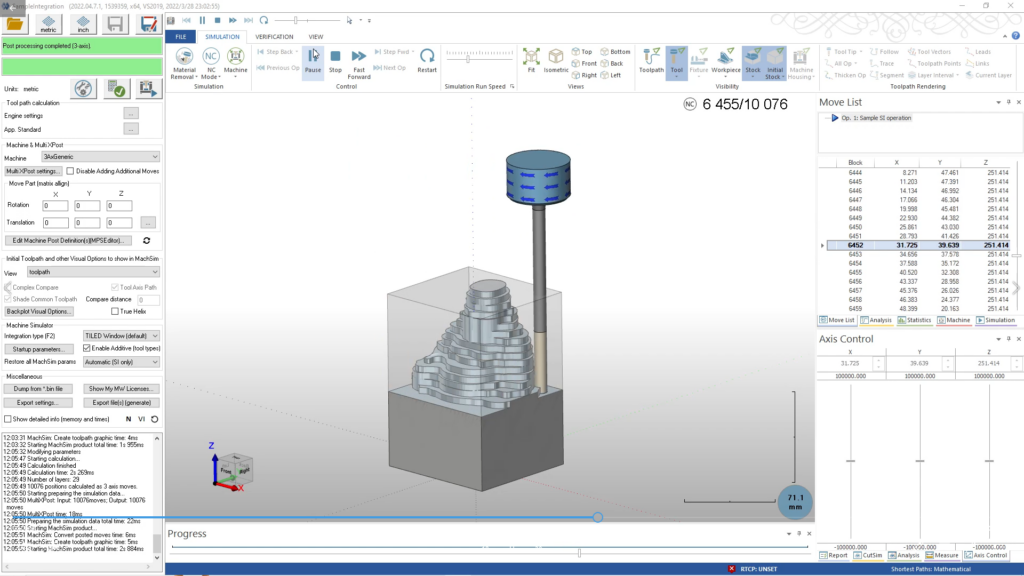

Machine simulation

Optional integrated graphical simulation environment that provides a virtual representation of the machine tool showing the movement of all axes, linear and rotary, in order to avoid problems on the machine during CNC program execution.

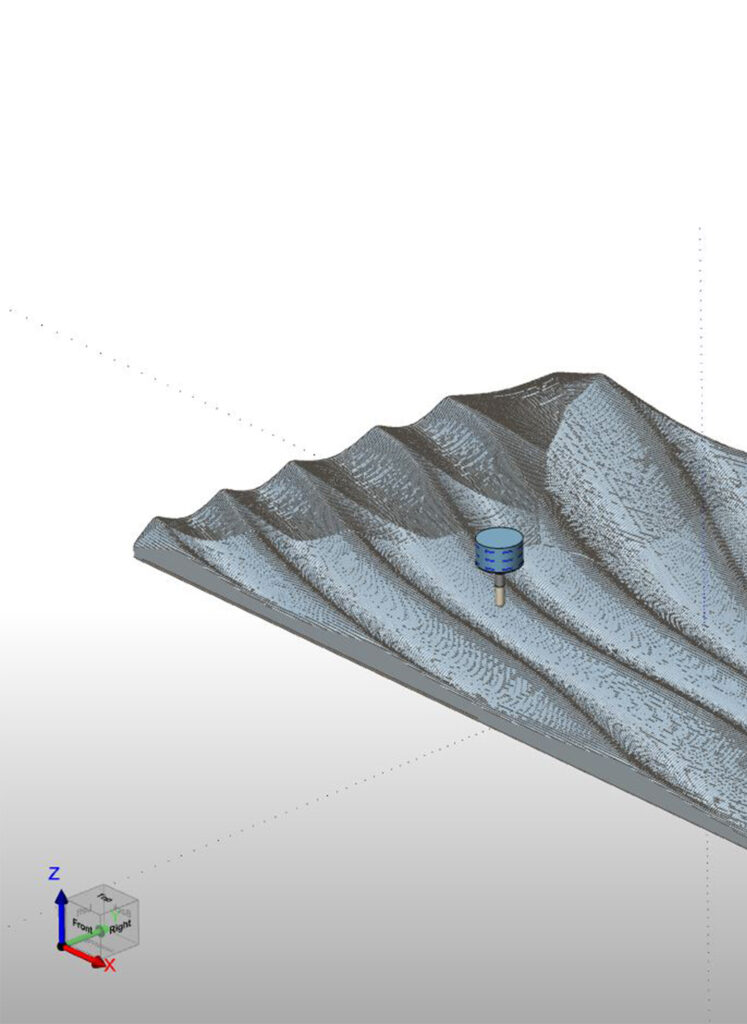

Workpiece simulation

Integrated graphical simulation environment of the results of all types of machining to check for possible collisions on both the blank and the finished model through toolpath and material removal.

Set-ups

Module for the correct positioning of workpieces on the machine tool table, which are then further checked during simulation. Sub-pieces (suction cups, stoppers, vices) can be associated to each workpiece.

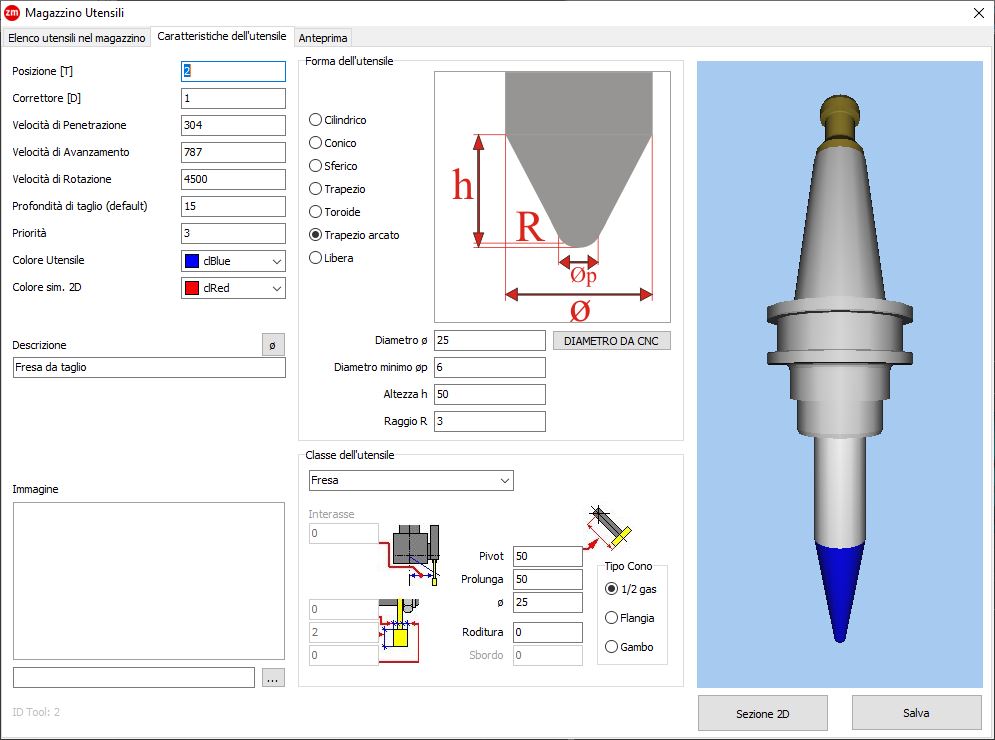

Tools

The software supports a variety of tools: cylindrical, spherical, toroidal, conical, engraving cutters, drills/forks, bushes, polishing wheels, free-form, discs and horizontal discs. Each tool can be equipped with a tool holder and casing/cap.

Tool archive

Presence of a virtual environment for the tool management of the CNC machining centre through one or more tables that can be configured as required.